LESS ENERGY, MORE CROP FOR EVERY DROP

Padu S. Padmanaban is the former Program Director of the…

A farmer’s dilemma, a city dweller’s nightmare.

Standing by the edge of his withering paddy field, Raj Kumar, a farmer who owns a small farm in Dodaballapur at the outskirts of Bangalore city in the Indian state of Karnataka, looks anxious as he scans the sky looking desperately for rain-laden clouds. His land is parched and he fears that if the rains fail his crops will perish. His only other source of water is groundwater whose level has fallen precariously. Compounding the problem further is the unreliable supply of electricity. This means the pumps are not operational when the need for water is greatest, and the poor quality of power supply makes pumping a risk since the cost of rewinding burned-out motor coils because of fluctuating voltage conditions is an additional expense that Kumar can ill afford.

In the city, the scenario plays out a little differently. Manjunath, an IT professional, is anxious too. The underground water sump in his modest, single storey home is almost empty. City dwellers like him are held hostage to the infrequent and inadequate supply of municipal water. The only alternative for Manjunath is to depend on costly tanker water obtained from unscrupulous contractors who purloin water from the city’s outskirts and truck it to its citizens. Ironically, the very groundwater that Raj Kumar the farmer seeks, is now being eyed by these contractors to satiate the demand of the city dwellers. Nowhere is the link between water, energy, poverty alleviation and equity is more stark, creating a cycle that often spins out of control. Raj Kumar’s dilemma for economic survival and Manjunath’s nightmare of living with water scarcity are formidable challenges. To address these, one needs to take a step back and understand the water-energy nexus (WEN) and its implications.

Understanding and managing the water-energy nexus is key for sustainable development

Unpacking the water-energy nexus

Energy for water, and water for energy – relatively unexplored, these are tightly interlinked, highly interdependent and branded as the water-energy nexus (WEN). Choices made in one domain have direct or indirect consequences on the other, positive or negative. The type of freshwater source influences the amount of energy required for irrigation. The nature of the manufacturing process determines the amount of water required to produce an industrial product. The form of energy generation being pursued determines the amount of water required to produce that energy.

Figure 1 shows WEN as the intersection between energy and water resources. This “definition” oversimplifies the relationship of the water and energy segments. In analysing the WEN concept further, researchers[i] have deconstructed the WEN Opportunity Space into six categories as indicated in Figure 2.

Fig.1: Early visualization of WEN concept

Fig. 2: WEN Opportunity Space

Global water and energy demand

Water plays a very important role in the world’s economy – from manufacturing, to agriculture, to energy generation and global transportation of goods and services. According to the AQUASTAT database[ii], 3856 km3 of freshwater was withdrawn for domestic, industrial and agricultural purposes globally around the year 2003. A decade later, in 2013, global freshwater withdrawal increased to 3945 km3. Most of it was used in the agricultural sector (70%), followed by the industry (19%) and domestic (11%). Figure 3 shows total freshwater use by sector in select countries. Driven by increased water needs in emerging markets – such as in China and India – global water demand is expected to rise to about 6,350 km3 in 2030.

Water and energy consumption in India.

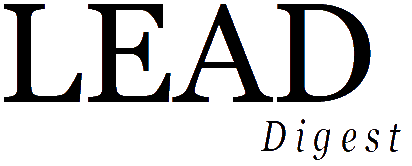

Estimates of sectoral water demand in India indicates that the largest user of freshwater is agriculture, followed by domestic and industry (including thermoelectric utilities). Figure 4 below shows sectoral water demand estimates in India from 1990 to 2050. In 2010, agriculture accounted for a total freshwater withdrawal of 388 million gallons per day (MGD), industry and energy together were 30 MGD, and residential was 84 MGD.

India’s landmass extends to nearly 3.3 million sq km. Almost half its lands, about 145 million hectares (Mha) are under sown areas of cultivation with about 36.7% of total agricultural land irrigated by groundwater and surface water, and the balance rain-fed. At 39 Mha, India has the world’s largest groundwater irrigation system (China with 19 Mha is second, USA with 17 Mha is third). Groundwater withdrawal is an energy intensive operation resulting in a fourth of the power consumption in the country being used for roughly 50 percent of the national irrigation water consumption. With about 21 million electrical pump sets and an additional 9 million diesel operated pump sets, India has more than four times the number of irrigation pump sets of China, Iran, Mexico and the USA combined.

With uncertain power availability, farmers tend to pump when power is available rather than when crops need water. This leads to over-extraction of groundwater, evaporation loss and lowered water tables, with farmers using high-capacity pumps to lift water from ever deeper levels. The subsidized tariffs for farmers in Indian states and free power in some has contributed to the overexploitation of ground water. There is an interesting tale dating back to the green revolution of the late 1960s in the state of Andhra Pradesh (AP). Farmer pumps were metered and utility personnel came by every month to note the meter readings. It was a manual operation that was both tedious and time consuming. A junior official had a brainwave. “Why not”, he suggested to his superiors, “we introduce a flat-rate metering system, where farmers would have to pay a fixed monthly cost based on the horse-power capacity of their pump. That way there will be no need for meters nor meter readers”. The suggestion was acted upon and soon the idea spread to other districts in the state and eventually to other Indian states.

The arrangement worked well until the late 1980s when the number of pump-sets in the country began to sky rocket. As long as it was in the low hundred thousands, even with low cost recovery, the financial impact to the utility was marginal. In succeeding years, with the growth in pump sets, the losses grew and utilities had to resort to cross-subsidization by increasing industrial and commercial tariffs. The state governments stepped in with a direct subsidy to the utility to cover their losses. The total all-India state power subsidy in 2008-09 was estimated at around ₹ 50,000 crores ($6.6 billion). This represented more than 20 percent of the total all-India state fiscal deficit in that year and is comparable to the country’s annual expenditure for education and more than double its expenditure for health.

Coping with uncertainties

With flat rate tariffs, the marginal cost of pumping water was zero. This led to unintended consequences. The watering habits of farmers took on a wasteful pattern. A commonly observed tactic employed by them was to keep the motor starter switch in the “on” position all the time. And when power supply came on, the water gradually flooded the fields until the power supply was switched off. This and other wasteful practices began to exact a heavy toll on groundwater levels in the country.

Many regions in India are witnessing shortages in water supply, with ground water levels falling as much as 1 meter every three years – to the point where they are 15 to 25 meters below their level 50 years ago. In Coimbatore, a city in the southern state of Tamil Nadu, groundwater levels have precipitously fallen to over 1000 feet. Farmers have resorted to what is euphemistically termed as “competitive drilling”. When a farmer sinks his bore well to a depth that enables him to tap groundwater, a neighbour drills further lower to access the same pool of water from the aquifer that serves them both. And the cycle continues till the well is bone dry signalling them to move further afield. In many parts of Mehsana district in the west Indian state of Gujarat and most of Rajasthan state, the horsepower of electric motors has undergone a sea change – a 5 hp motor-pump system has been replaced by 15 hp and higher capacities. Approximately 12 percent of all aquifers are severely overdrawn, and the problem is exacerbated by the runoff of surface water. As of 2020, the Central Ground Water Board has estimated over exploitation of ground water in over 800 industrial projects and 162 areas, deemed as critical, across the country.

As one speaker at an energy conference eloquently put it “If you visualize India as one gigantic well, we have reached a stage where the current level of groundwater extraction is exceeding recharge and is therefore unsustainable”. While three states, Punjab and Haryana (the bread baskets of India) and Rajasthan have reached this phase, three others – Tamil Nadu, Gujarat and Andhra Pradesh are fast approaching that inevitable point.

There were other consequences as well. Overexploitation of groundwater is also a significant contributor to India’s growing carbon emissions (estimated at 1-1.5%) as considerable pumping energy is required to extract even deeper water supplies from aquifers that have not been mined for millions of years. In addition, over withdrawal and the lack of effective groundwater management strategies, such as aquifer recharge has led to the widespread use of lower-quality groundwater, exposing affected populations to long-term health risks from fluoride, increased salinity and microbiological contamination.

Motor burnouts on account of fluctuating voltages due to poor quality of power supply is a frequent occurrence. In order to protect the motors from failing frequently the farmers tended to install inefficient motors with thicker copper windings that can withstand higher temperatures. A popular narrative was that dealers in pumps in manufacturing hubs like Rajkot or Coimbatore, had a simple question to ask of the farmer – “Which part of the country or district do you hail from?” The shop keeper would then offer the customer a higher horsepower motor that was customised for the power quality of that place! These make-shift motors with thicker windings and lower efficiency created a ripple effect that tended to overload the local distribution transformer. This in turn, in a short period, would blow out requiring to be replaced by a higher capacity transformer. And this vicious cycle continued, spiralling out of control. This trend needed to be replaced by a virtuous cycle. A pilot demonstration project at Doddaballarpur, a rural district in the outskirts of Bangalore city did just that.

The WEN pilot project

The agricultural pilot site at Doddaballarpur was spread over a total area of 11,000 acres with a total cultivated area of 7300 acres (64%) of which 1700 acres was irrigated by a combination of groundwater (23%) and rainfed cultivation (77%). The major produce from groundwater irrigation was horticultural products with grape and mulberry accounting for almost 59% of the total ground water consumption.

The pilot interventions reduced both water and energy consumption while enhancing farm incomes. These interventions followed upon a yearlong survey conducted on all bore wells to analyse, measure and record energy and water usage patterns as well as agricultural farming practices. There was in total 947 irrigation pump sets with an energy savings potential estimated to range between 25-40% with an additional potential of 15-25% through the adoption of efficient irrigation methods like drip irrigation, construction of bunds and check dams.

Promotion of drip irrigation

The Bangalore electricity distribution utility provided all the preconditions for the project such as redesign of cables to reduce energy losses, installation of high voltage distribution system to minimize voltage drop and installation of distribution transformers for each pump.

Each farmer received a brand-new pump set free with an 18-month warranty. 280 pump sets were replaced resulting in energy savings of approximately 1.5 million kWh per annum (33% saving) due to implementation of this project which, in turn, can power an additional 3500 rural households in the state. A private water-energy services company financed the investment required for the pump and provided on-going operation and maintenance support to farmers. As per the terms of the performance contract agreement, the company was allowed to recoup its investments through a shared energy savings agreement with the distribution utility.

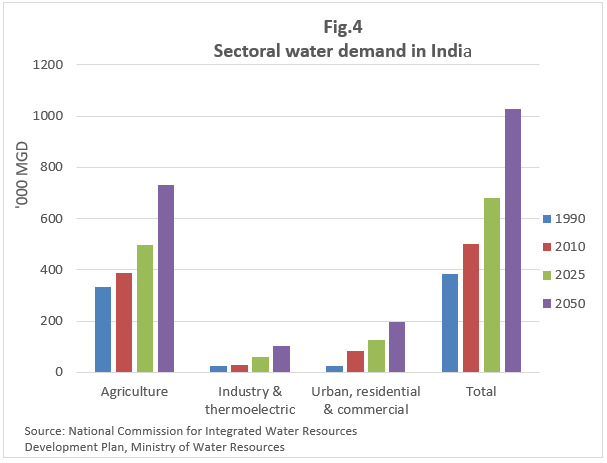

Several challenges were faced. These are illustrated in Figure 5 below. All these challenges were overcome along the way through dialogue with local NGOs who represented farmer interests and the development of a bankable business model that addressed the risk perception of the stakeholders.

Fig.5: Challenges faced

Acronyms: HT – High Tension; LT – Low Tension; DT – Distribution Transformer; WESCO – Water & Energy Services Co.; O&M – Operation & Maintenance.

Conclusion

The pilot had successfully transformed the vicious cycle that farmers like Raj Kumar frequently encountered to a sustainable outcome that was reflected in better power supply quality, lower electricity and motor maintenance costs and rising levels of groundwater in their bore wells. This project also won Platts Award for Excellence in 2012 and India Power Awards in 2009. Looking ahead, one has to chart a strategic blend of crop produce that is water efficient and design watershed initiatives that yields two crops a year with the quantum of water they can harvest; introduce water management of plants and crops through drip irrigation; construct farmer operated storage systems for water that are native to the region and cost-effective, bunds and revetments, and surface water harvesting tanks. At each of the steps there is a combination of higher yield, lower water use and lower energy use – less energy, more crop for every drop.

About the author: Padu S. Padmanaban is the former Program Director of the South Asia Regional Initiative for Energy and Senior Energy Advisor for USAID/India’s bilateral program. He has served with the World Bank, Washington DC as an Energy Efficiency Specialist and is a visiting fellow with the King Abdullah Petroleum Studies and Research Center at Riyadh. He is a recipient of several international and national awards in energy management, the latest being the Regional Energy Manager of the Year 2019 Award by the United States Association of Energy Engineers. Know more about him by clicking on the author link.

[i] This section draws upon pioneering work conducted by the Midwest Energy Research Consortium (M-WERC) in developing a strategic EWN roadmap. http://m-werc.org/

[ii] AQUASTAT Data base (Food & Agriculture Organization, FAO, 2010)

(Note: Unless mentioned, images and figures are as provided by the author)

What's Your Reaction?

Padu S. Padmanaban is the former Program Director of the South Asia Regional Initiative for Energy (SARI/E) and Senior Energy Advisor for USAID/India’s bilateral program. He has served with the World Bank, Washington DC as an Energy Efficiency Specialist and is a visiting fellow with the King Abdullah Petroleum Studies and Research Center (KAPSARC), Riyadh, Saudi Arabia. He has over four decades of experience in the design of national and regional energy efficiency programs, power sector reforms, regional energy integration, energy-water nexus, clean energy and energy access projects including the planning and establishment of national and regional centers of excellence in energy efficiency. He is a trustee of Alttech Foundation, a Bangalore based NGO devoted to advancing water-energy sustainability and also is the founder member of the Alliance for Energy Efficient Economy (AEEE), India. Padmanaban is the recipient of several international and national awards in energy management and efficiency. These include: The Regional Energy Manager of the Year 2019 Award by the United States Association of Energy Engineers; the World Clean Energy Award, 2007 by the Swiss based Transatlantic 21 in global recognition of his achievements in advancing energy efficiency and renewable energy. Recipient of the Hall of Fame Award by the Indian Green Building Council in 2013, the All-India Power award in 2010, and the Energy Professional Development award, 2008 by the Association of Energy Engineers, India.

Padmanaban taught at the School for Advanced International Studies (SAIS), Johns Hopkins University, Washington DC. He has a B.E. in Mechanical Engineering from the University of Madras (1973), a PG certificate in Fuel Efficiency (1974-76) from National Productivity Council, India and Diplomas in Energy Management from UCTI-IRI, Rome (1981) and ILO, Turin (1983), Italy.